Highlights

- High chemical resistance

- Resistant to UV radiation

- High resistance to temperatures (110°C and up to 160°C in the Zotek F 75HT version)

- High purity (FDA approval, cleanroom FM4924, compatible 4910)

- Biological inertia (test ASTM-G21-96)

- Thermoformable

Zotek® F

PVDF

DESCRIPTION

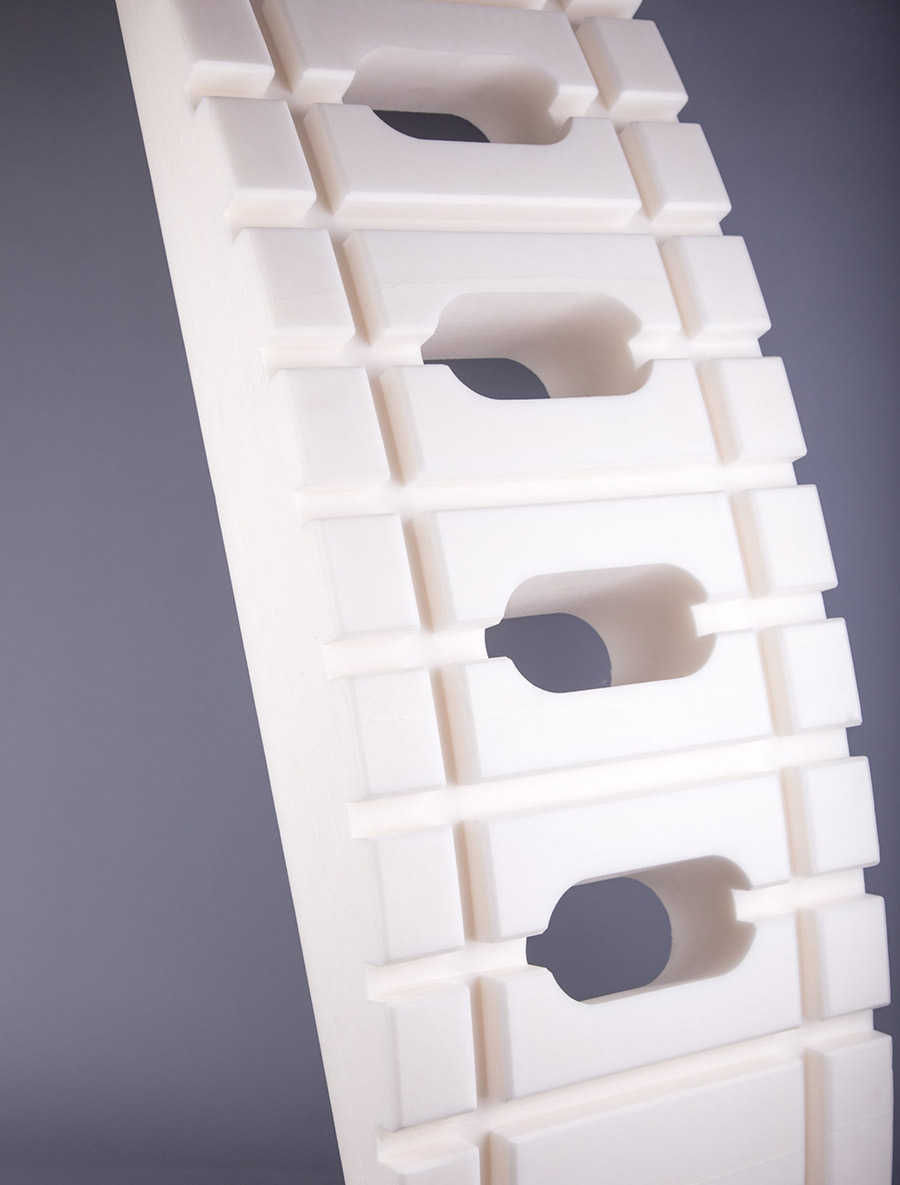

Zotek® F is a high-performance PDVF (polyvinylidene fluoride) expanded plastic material. Its main characteristics include excellent chemical resistance to UV radiation and high resistance to temperatures and flames. These properties explain its use in the aerospace, pharmaceutical and medical sectors.

SUPPLY

Thicknesses and dimensions, even for small series, made adhesive, milled, die-cut to a design, waterjet-cut and thermoformed.

USES

INDUSTRY

- Protective packaging in container

- Anti-vibration components

- Trays and supports for transport and storage

- Impermeable seals

- Heat and sound insulation

- Cable container, cable duct, accessories and components

CERTIFICATIONS

Aerospace

Compliant with FAR 25.853 standards Appendix F PT (A) (II) vertical burner, PT (IV) heat release, PT (V) smoke density. ABD0031; OSU 65/65. NASA-APPROVED.

Compliant with FAR 25.853 standards Appendix F PT (A) (II) vertical burner, PT (IV) heat release, PT (V) smoke density. ABD0031; OSU 65/65. NASA-APPROVED.

Medical sector

Compliant with ISO 10993 (USP 611) for medical equipment.

Compliant with ISO 10993 (USP 611) for medical equipment.